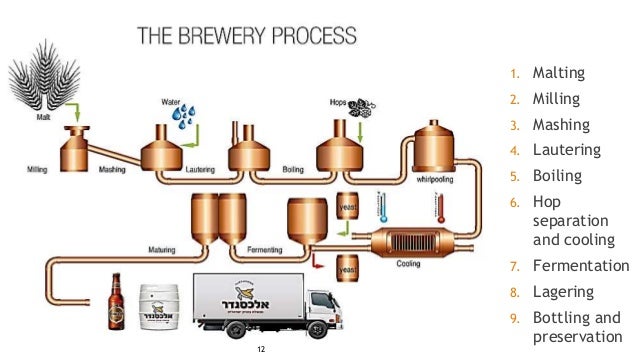

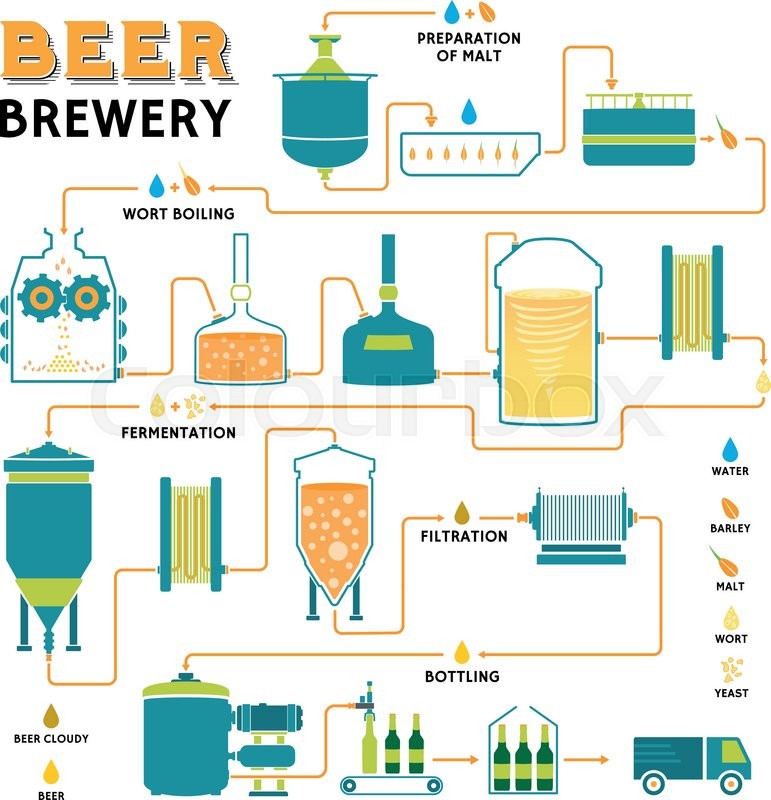

Process of beer fermentation

Home » Food and Drinks » Process of beer fermentationProcess of beer fermentation

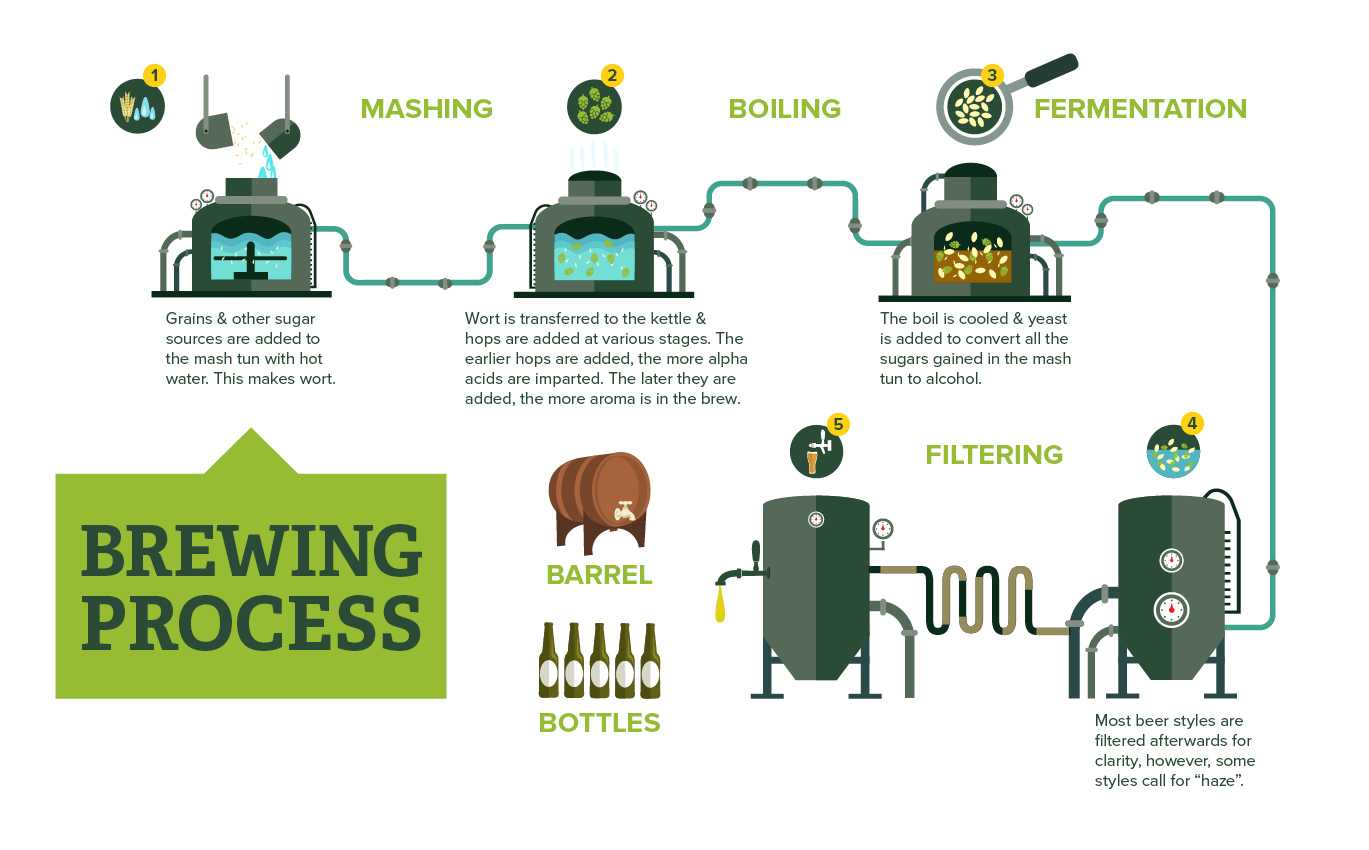

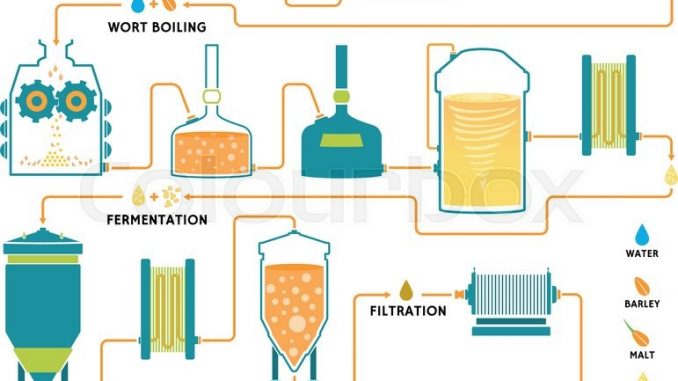

Process Of Beer Fermentation. To start the fermentation process beer yeast is added while the fermentation vessel is feeling filled. To begin the fermentation process the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. Stationary stage Beer gravity will drop. Beer is cooled to keep temperature constant all the time.

Rodenbach From palm.be

Rodenbach From palm.be

Yeast helps to convert wort sugar into alcohol releasing carbon dioxide during the process. A beer wort steeping at the right temperature. As a business they are also trying to sell as much of their product as possible and less beer fermentation time means more brews. Glucose is converted into ethanol alcohol and carbon dioxide a gas. Bottling and aging After fermentation beer need to mature in order to develop flavor and for carbonation effect. The brewing process typically takes around 90 minutes.

As a business they are also trying to sell as much of their product as possible and less beer fermentation time means more brews.

As a business they are also trying to sell as much of their product as possible and less beer fermentation time means more brews. The basic beer fermentation process is the same as a normal yeast fermentation process. Stationary stage Beer gravity will drop. It ferments malt sugars producing carbon dioxide and alcohol. Glucose is converted into ethanol alcohol and carbon dioxide a gas. A beer wort steeping at the right temperature.

Source: ibdasiapac.com.au

Source: ibdasiapac.com.au

Four Stages of Beer Fermentation cont 2. Bottling and aging After fermentation beer need to mature in order to develop flavor and for carbonation effect. Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas CO 2 to give beer its alcohol content and carbonation. A beer wort steeping at the right temperature. Now it is a sugary liquid ready to be fermented into delicious beer or a mash that can later be distilled into whiskey or vodka.

Source: britannica.com

Source: britannica.com

It ferments malt sugars producing carbon dioxide and alcohol. Foam is seen on surface of beer. Yeast is the secret behind high-quality beer production. Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas CO 2 to give beer its alcohol content and carbonation. Yeast helps to convert wort sugar into alcohol releasing carbon dioxide during the process.

Source: grainfather.com

Source: grainfather.com

After fermentation is complete the liquid is called Green Beer. Now it is a sugary liquid ready to be fermented into delicious beer or a mash that can later be distilled into whiskey or vodka. Fermentation Fermentation is the process whereby sugars are converted by yeast to alcohol carbon dioxide and heat. The basic beer fermentation process is the same as a normal yeast fermentation process. The initial vigorous fermentation process may be over in 4-5 days but the yeast are still happily working away.

Source: slideshare.net

Source: slideshare.net

Beer is cooled to keep temperature constant all the time. Fermentation is the process by which yeast converts the glucose in the wort to ethyl alcohol and carbon dioxide gas – giving the beer both its alcohol content and its carbonation. A beer wort steeping at the right temperature. Foam is seen on surface of beer. The basic beer fermentation process is the same as a normal yeast fermentation process.

Source: foodcrumbles.com

Source: foodcrumbles.com

Yeast is the secret behind high-quality beer production. After fermentation is complete the liquid is called Green Beer. However a lot more happens during fermentation than just the formation of these two molecules. Glucose is converted into ethanol alcohol and carbon dioxide a gas. In most cases the minimum time that you should leave your beer to ferment is about 10 days.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

In the brewing of most traditional beer the sugars are derived mainly from malted barley although other cereal sources and other plant sugars can also be used. However a lot more happens during fermentation than just the formation of these two molecules. In most cases the minimum time that you should leave your beer to ferment is about 10 days. The fermentation process starts when cooled wort is transferred to a fermenting vessel and yeast is added. Beer is cooled to keep temperature constant all the time.

Source: researchgate.net

Source: researchgate.net

The fermentation process starts when cooled wort is transferred to a fermenting vessel and yeast is added. Stationary stage Beer gravity will drop. Yeast is the secret behind high-quality beer production. Fermentation Fermentation is the process whereby sugars are converted by yeast to alcohol carbon dioxide and heat. The basic beer fermentation process is the same as a normal yeast fermentation process.

Yeast helps to convert wort sugar into alcohol releasing carbon dioxide during the process. After this the brewed grains are removed from the liquid called wort. The brewing process typically takes around 90 minutes. Foam is seen on surface of beer. Yeast produces a whole range of flavoring components during fermentation.

Source: aslanbrewing.com

Source: aslanbrewing.com

Fermentation Fermentation is the process whereby sugars are converted by yeast to alcohol carbon dioxide and heat. However a lot more happens during fermentation than just the formation of these two molecules. Beer is cooled to keep temperature constant all the time. The brewing process typically takes around 90 minutes. Stationary stage Beer gravity will drop.

Source: usahops.org

Source: usahops.org

In most cases the minimum time that you should leave your beer to ferment is about 10 days. The basic beer fermentation process is the same as a normal yeast fermentation process. The fermentation process starts when cooled wort is transferred to a fermenting vessel and yeast is added. A beer wort steeping at the right temperature. Glucose is converted into ethanol alcohol and carbon dioxide a gas.

Source: onlinebiologynotes.com

Source: onlinebiologynotes.com

Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas CO 2 to give beer its alcohol content and carbonation. The fermentation process starts when cooled wort is transferred to a fermenting vessel and yeast is added. It includes esters phenols and a wide selection of other chemicals. Beer is cooled to keep temperature constant all the time. Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas CO 2 to give beer its alcohol content and carbonation.

Source: palm.be

Source: palm.be

Glucose is converted into ethanol alcohol and carbon dioxide a gas. To begin the fermentation process the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. Four Stages of Beer Fermentation cont 2. However a lot more happens during fermentation than just the formation of these two molecules. After fermentation is complete the liquid is called Green Beer.

Source: blog.beeriety.com

Source: blog.beeriety.com

Bottling and aging After fermentation beer need to mature in order to develop flavor and for carbonation effect. Beer is a carbonated alcoholic beverage obtained by alcoholic fermentation of malt wort boiled with hops. Bottling and aging After fermentation beer need to mature in order to develop flavor and for carbonation effect. Fermentation is a process whereby yeast converts glucose in the wort to ethyl alcohol and carbon dioxide gas CO 2 to give beer its alcohol content and carbonation. In most cases the minimum time that you should leave your beer to ferment is about 10 days.

Source: czechminibreweries.com

Source: czechminibreweries.com

Yeast produces a whole range of flavoring components during fermentation. The initial vigorous fermentation process may be over in 4-5 days but the yeast are still happily working away. Foam is seen on surface of beer. The fermentation process starts when cooled wort is transferred to a fermenting vessel and yeast is added. However a lot more happens during fermentation than just the formation of these two molecules.

Source: birrificio.it

Source: birrificio.it

The initial vigorous fermentation process may be over in 4-5 days but the yeast are still happily working away. Yeast produces a whole range of flavoring components during fermentation. To begin the fermentation process the cooled wort is transferred into a fermentation vessel to which the yeast has already been added. It includes esters phenols and a wide selection of other chemicals. During fermentation yeast converts the sugary wort into actual beer by producing alcohol a wide range of flavours and carbon dioxide which is used later in the brewing process to carbonate the beer.

If you find this site good, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title process of beer fermentation by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.